Services

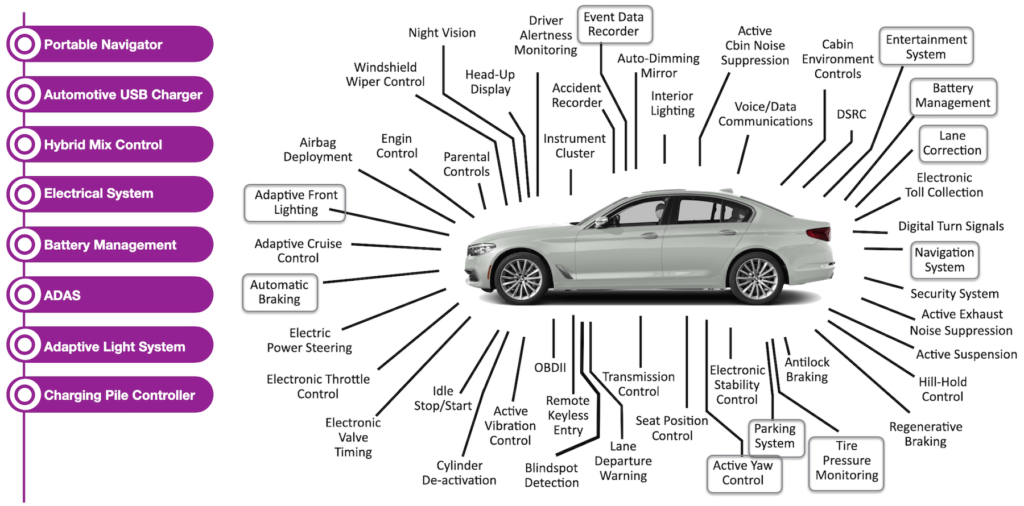

With the advancement of science and technology and rapid development of communication technology, whether it is applied to the EV motor system of EV car and the Internet of Vehicles or the end application products in the home, its safety and reliability have gradually attracted attention.

Different from general consumer electronics and electrical products, the life cycle of automotive products is more than 10 years, so the requirements of safety、reliability、application system functions and other requirements, software, hardware and system integration related development processes, products The rigor and safety of product design is a major challenge for major manufacturers in the supply chain.

The reliability of consumer products has also evolved from being not durable in the past to today’s smaller size or longer product life.

Focus on electronics, electric motors, vehicle electrical control to safety lighting, TOTEN Technology co-work with RDM’s localization expert team to provide undifferentiated services. The debugging capability has been recognized by automotive product suppliers and major system vendors in various countries. We have complete debugging experience for various electronic products in North America, Japan, Taiwan and India.

TOTEN Technology also cooperates with third-party testing and verification companies to provide customers with a complete set of debugging experience with a better experience.

As the design of electronic parts becomes more and more miniaturized, testing and debugging make system vendors face more and more challenges

Including the selection and layout of parts to the PCB board design, the difficulty is getting higher and higher. TOTEN Technology provides professional EMC modification services, and provides customers with acceptable electromagnetic interference countermeasures according to customer needs, and provides material to customers within the shortest lead time.

Customers can provide Circuit design and Layout design files and EMI test reports. After receiving relevant test reports and data then evaluate them immediately, and they can also analyze possible future EMI countermeasures through actual on-site measurements. TOTEN Technology and RDM work together provide debugging experience for the following categories

Debugging Service Categories :

- Automotive

- Bio-Medical

- Military

- Communication

- Industries

- Consumer

- Optical

- Other Experience >

With the stringent electromagnetic interference regulations in various countries, traditional PCB layout is no longer adequate

After years of debugging experience big data, we’ve indeed achieved a single-point design/multi-point thinking of EMI Layout, so that the layout problem can be solved for the first time, makes the final PCB layout can be completed quickly, and finally be a perfect PCB board design, fast and effective

TOTEN Technology provides the following equipments for customers to rent

EMI Chamber

Built 2 sets of 7M x 5M x 5M EMI Chamber for Automotive and Commercial level

ESD Table

Measurement range reached to ±30KV

Programmable constant temperature and humidity testing machine

Humidity:10%~98%R.H

Temperature:-40℃ ~ 125℃

Including the selection and layout of parts to the PCB board design, the difficulty is getting higher and higher. TOTEN Technology provides professional EMC modification services, and provides customers with acceptable electromagnetic interference countermeasures according to customer needs, and provides material to customers within the shortest lead time.

Customers can provide Circuit design and Layout design files and EMI test reports. After receiving relevant test reports and data then evaluate them immediately, and they can also analyze possible future EMI countermeasures through actual on-site measurements. TOTEN Technology and RDM work together provide debugging experience for the following categories

The debugging experience includes most products currently on the market

Generally speaking, it’s about 50% to 55% of fuel vehicles are plastic or non-electrical products, such as tires, steel plates or glass, etc. At present, the accumulated experience of debugging experience of existing fuel vehicles is as high as 85% most

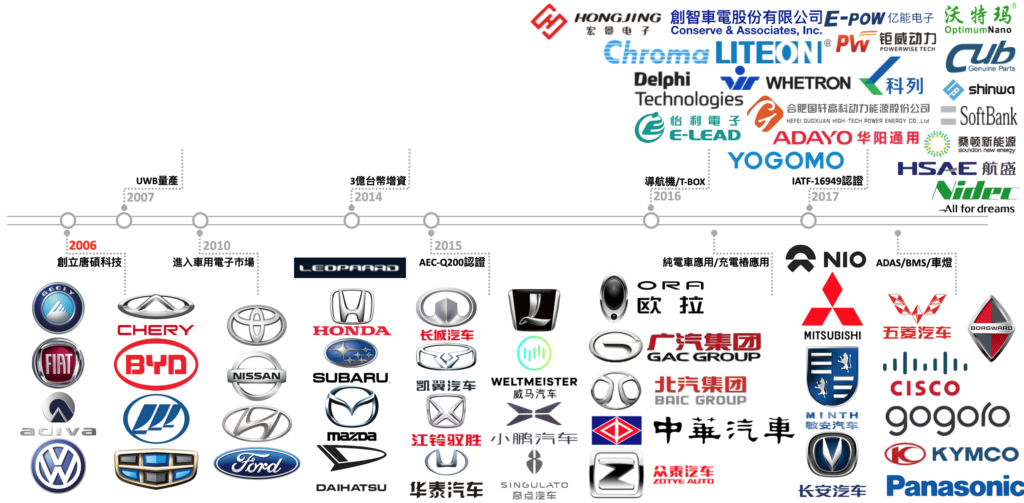

Current customers in automotive market are listed below and are being updated continuously